|

5-lug suspension from '84 944, w/ 4-wheel vented disc brakes, available on the 924 and 931 as option M471, using KFP Magnum ".03" Blue race pads (front and rear), with stock-replacement Brembo rotors. | |

|

Rims are 15"x6" all around, stock 924 spider-web rims for dry tires (Hoosiers or Michelins) and the rains (Hoosier Dirt Stockers). | |

|

Shocks and struts are custom-valved Bilstein Motorsport units front and rear, with Paragon Products adjustable camber plates and KLA strut tower brace up front. | |

|

Springs, torsion bars, and swaybars are upgraded except for the front swaybar- 400lb Carrera front springs, 30mm Sway-a-Way rear torsion bars, 22mm front swaybar (stock), 19mm adjustable Porsche 944 Cup Car rear swaybar. The rear swaybar also has KLA's adjustable-length end-links with spherical bearings, to remove any pre-load from the rear swaybar. The front swaybar still needs this feature. | |

|

Front bushings have all been replaced with spherical bearings from Shine Racing. Rear spring plate bushings have been replaced w/ Racer's Edge delrin and Weltmeister poly-graphite bushings. The rear trailing arm rubber bushings have been replaced with Racer's Edge spherical bearings. The only rubber remaining in the suspension is some of the less-important rear suspension mounts. |

The interior is fairly well stripped, but retains the dashboard (and center console, not required) as per IT rules. Everything else is removed to facilitate installation of the roll cage. Carpet and sound-deadening have been removed to reduce weight, and a full cage with door bars (for side-impact protection) has been welded in. The seat is a Kirkey aluminum circle-track seat. Additionally, a full fire-suppression system is installed (extinguisher ports at intake, fuel tank, and driver's feet), plus the usual racing safety gear of 6-point harness, electrical cutoff switches, and window net.

An AIM Motorsport data-acquisition unit has been fitted, replacing much of the original dash function with speed readout, tach, shift lights, warning lights, and lap times. An oil temp gauge has replaced the clock in the center console, reading temps from the oil filter (prior to where the oil enters the oil cooler). An additional oil pressure warning light is added between the tach and speedo. The rear seat has also been removed. A Momo steering wheel with quick-release has been added. An aux starter switch and an aux rad fan switch have been added. A larger rearview mirror has been added, and a camera mount bolts to the roll cage for the videocamera.

![]()

Here's a few details of some specific race-related points of the construction/preparation of my car for IT Racing.

MYCHRON3 DATA ACQUISITION SYSTEM

SAFETY FEATURES - details of interior net installation, etc.

OIL COOLER INSTALL - Cooler, Remote Filter Head, Oil Temp Gauge

INTERIOR - Quick-Release Steering Wheel, Fire Bottle

![]()

All European Auto Supply - excellent prices on replacement stock components, they actually specialize in Volvos (!), but race them in IT, are very serious about supporting local racers, give great prices and service, and are just generally great guys to deal with!

Paragon

Products - Source for performance parts for Porsches, and not just 911's! Actually

my source for most of my off-the-shelf aftermarket suspension components. Excellent

prices and service.

Paragon

Products - Source for performance parts for Porsches, and not just 911's! Actually

my source for most of my off-the-shelf aftermarket suspension components. Excellent

prices and service.

![]() KLA Industries - Another recent addition,

specializing in new fabrication parts designed explicitly for our cars. The strut

tower brace and rear swaybar adjustable endlinks are from KLA Industries.

KLA Industries - Another recent addition,

specializing in new fabrication parts designed explicitly for our cars. The strut

tower brace and rear swaybar adjustable endlinks are from KLA Industries.

OG

Racing - Source for a couple of my race components - full roll cage specially

designed for the 924/944, and the firesystem.

OG

Racing - Source for a couple of my race components - full roll cage specially

designed for the 924/944, and the firesystem.

Racer

Parts Wholesale - General good cheap source for race parts (generally

non-car-specific).

Racer

Parts Wholesale - General good cheap source for race parts (generally

non-car-specific).

RJS Racing - Local (Detroit area) safety equipment manufacturer, great stuff, good prices, sells their stuff to quite a few national distributors.

Racer

Wholesale - Sister store to RPW (Racer's Parts), handles only the safety stuff,

not the hardware/parts.

Racer

Wholesale - Sister store to RPW (Racer's Parts), handles only the safety stuff,

not the hardware/parts.

Pegasus

Racing - General source for road-racing racer's stuff, decent prices, incredibly

comprehensive catalog.

Pegasus

Racing - General source for road-racing racer's stuff, decent prices, incredibly

comprehensive catalog.

Summit

Racing - Yeah, the drag/roundy-roundy place! However, they have a lot of the same

stuff as Pegasus, for less.

Summit

Racing - Yeah, the drag/roundy-roundy place! However, they have a lot of the same

stuff as Pegasus, for less.

![]()

MyChron3 Gold XG Car Data Acquisition System/Dash Display

We've installed a new data acq. system (aka DAS) to both replace some of the dashboard functions and to track and store data during on-track sessions with the goal of improving both the tune of the car (suspension and engine) and the tune of the driver. The system consists of two boxes and a bunch of sensors. It tracks and displays engine RPM, vehicle speed, lap times (through the use of a lap marker beacon) and lateral acceleration (not displayed). It will also track and display up to 4 additional analog channels, to be used for temps, pressures, or other signals. We can use this to monitor exhaust gas temps (EGT's) to keep track of the engine mixture, and monitor engine tuning, or we can use them to monitor oil and water temps and pressures. We can also plug in other sensors to monitor acceleration, etc.

The display will also light warning lights on the analog channels, as well as RPM shift lights and a calculated gear indicator. The warning lights and RPM shift lights are all user-configurable. Here's pictures of the display.

|

|

|

| System on, showing bar RPM gauge and shift lights. | System on, shows the shift lights in a little better detail. | At idle. |

![]()

Latest suspension updates (as of April 2003) - Bilstein shocks and struts front and rear, and spherical bearing inserts for the rear trailing arms from Racer's Edge. Also a new Strut Tower Brace from KLA Industries. The shocks and struts have all been valved to match the current suspension setup.

New (actually rebuilt) Bilstein struts on the left, Koni Sport inserts coming off on the right:

The new rear Bilstein shocks - user-serviceable/revalveable:

KLA Industries Strut Tower Brace from 944Racing.com:

Car getting set straight on the alignment rack at work

400lb Carrera front springs, Hypercoil tender springs, adjustable spring perch kit from a Saturn SC2, Paragon camber/caster plates, Shine Racing spherical bearing kit on the A-arms, braided steel brake hoses, KFP Magnum ".03" Blue race brake pads, stock discs, Bilstein front struts (not shown), stock 22mm front swaybar, and some fresh Duplicolor spray can so I can see in there.

Note the brand-new swaybar endlinks.

KFP Magnum ".03" Blue race pads, braided steel brake hoses, Sway-A-Way 30mm torsion bars, 19mm adjustable 944 Cup Car rear swaybar, Bilstein revalveable circle-track shocks, Racer's Edge delrin outer spring plate bushings, Weltmeister poly-graphite inner spring plate bushings, custom-fabbed aluminum hard mounts to replace bushing material on the rear suspension, and spherical bearings on the trailing arms.

5-speed 924 trans (Audi-style - not shown here) with factory limited slip retrofitted from a 951 (944 Turbo) gearbox. Note all CV's are rebuilt, and the bolts are drilled and safety-wired to prevent backing out. (trans shown in this pic was an early 924 4-speed, since replaced)

![]()

INTERIOR

General cockpit layout w/ race seat, quick-release wheel, gauges, switch panel, and

firebottle. Camera mount goes on crossbar of main roll hoop near red strap (which is

actually the strap for the camera).

Detail of steering wheel installation. Momo Monte Carlo wheel is bolted to aluminum

adapter, which bolts to standard hex-type quick-release hub. The center steel portion

of the hub is welded to a sleeve welded to the stock steering column. The sleeve and

it's center support were made on the long side to bring the wheel closer, making the

driving position more comfortable. Large red thing on the dash above the ignition key

is an extra oil pressure warning light, in an easier location to observe while at

10/10ths! Red "blob" behind the wheel at the top is the red duct tape covering the

backside of an auxiliary electrical kill switch, easier for me to reach while strapped

in than the one on the hood. Stock turn signal and other steering column switch gear

are still in place and functional.(click for

even more detail of the steering wheel hub)

Another picture showing the gauges from an outside angle

Here's a shot of the fire bottle install. Upper line goes by my feet (one nozzle

there) then to the intake area of the engine compartment. The lower line goes back to

the gas tank through the hole for the filler neck.

Close-up of the center gauge cluster. More switches to come in the blank

aluminum panel (bottom), as time permits further development. Note the VDO oil temp

gauge in place of the clock in the center hole.Oil temps run needle vertical on track,

about 230-240 degrees F.

![]()

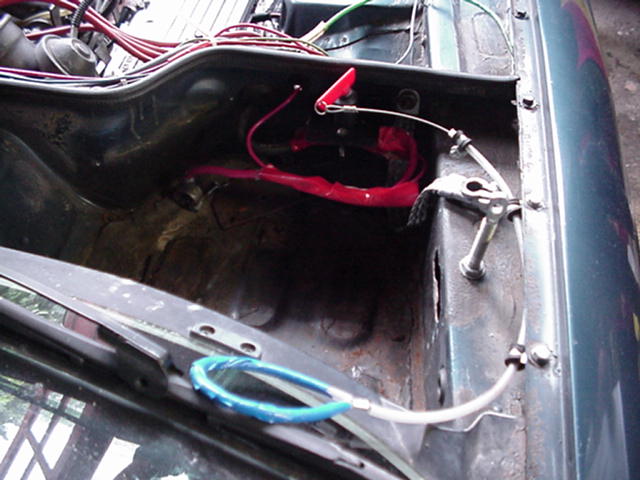

REMOTE BATTERY CUTOFF

Placed a battery cutoff switch next to the battery for easy external/passenger side

access, but used a cable pull mechanism (often seen in PCA, but quite unusual in SCCA)

to actuate it to avoid cutting a hole in the sheetmetal.Switch is shown in the ON

position; pulling the blue handle will open the circuit, isolating the battery and

killing the engine. The hood does have to be lifted to reset the switch.

![]()

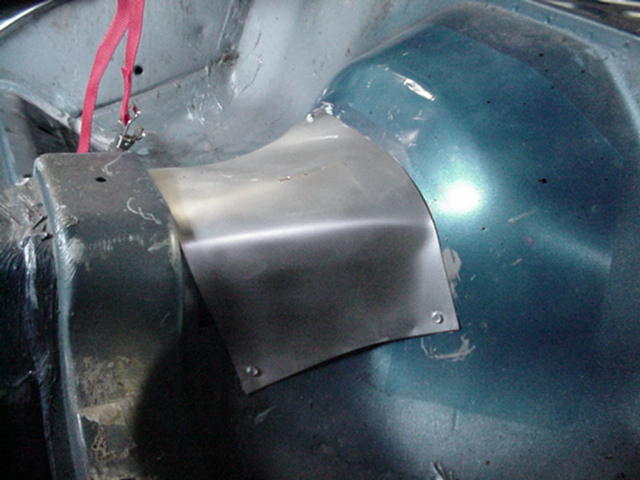

TRANS HUMP ACCESS CUTOUT

Not much to say about this one; carved a big hole in the rear trans hump (just

behind the main structural cross-hoop) to provide better access to the shift linkage

of the snailshell transmission.

![]()

Latest big addition was the installation of an oil cooler to assist in keeping temps down, both water and oil, and keeping oil pressure up even when running hard. It has done an excellent job of the latter, with hot idle oil pressure raised from 0.5bar to 2 bar, even immediately after pulling off the track.

The oil flow path is out of the adapter to the filter head, then to the oil thermostat, then to the cooler, then back to the block via the oil thermostat. I sourced all parts from Racer Parts Wholesale, just the cheap generic items, and the quality was fine. The rubber hose used for the initial installation has since been replaced for the 2001 season with proper Aeroquip hose and fittings for durability.

This means that I'm measuring the oil temp as it's coming out of the filter, before it goes to the cooler, as the sender unit is suspended over the center port of the filter, (the output side of the filter). I'm using a Diesel Wabbit filter, larger size for more filtering capacity. The location of the remote filter head also means that the filter itself acts as another cooler, being exposed to fresh airflow. The added plumbing, in all, adds about 1 quart of capacity to my system - another bonus!

While I suspect the oil thermostat may be overkill, as the oil cooler I have (Long brand) looks very sturdy, I do like having it to try to help speed-up the oil warm-up time, as the oil takes much longer to warm up than the coolant.

The cooler used is a fairly typical sort, zip-tied to the front of the radiator.

The additional bracketry was already on the cooler when obtained (through a swap), but helped provide a standoff between the oil cooler and radiator. Additionally, the position of the cooler on the left of the radiator positions it in front of the fan to ensure cooling even when at standstill. While some might take issue with the fact that the cooler is in front of the radiator, thereby raising the exit temp of the engine coolant, it is a far more protected location than below the radiator. This is further enhanced when the grille is installed, as the stock plastic grille is backed with 23GA hardware cloth to provide additional screening against rock damage.

The oil thermostat is located in front of the top right of the radiator; this will restrict oil flow to the cooler until the oil is warm enough, diverting it back to the engine instead. This protects the oil cooler from cold overpressure bursting and also reduces warm-up time.

The oil exits the block from an oil cooler adapter, not a sandwich plate.

...which improves space under the hot exhaust manifold and removes the oil filter to a cooler, more accessible location.

The oil cooler hose proceeds up to the filter...

which is now mounted to a remote filter head bolted to a bracket on the top of the

frame rail. Then the oil heads up to the cooler by way of the thermostat. The return

line passes back beside the filter head, wrapped in wire conduit to protect against

abrasion. When racing, the lines near the manifold are also wrapped in a heat shield

blanket. The blue wire to the top of the filter head goes to a VDO oil temp sender;

this measures the temp of the oil after passing through the filter, on its way out

from the engine. The VDO oil temp gauge sits in place of the clock in the center of

the center gauge cluster.